Exploring Hardware with Tom: A Comprehensive Guide

DIY Deliciousness: Exploring the World of 3D Chocolate Printing with CocoaPress

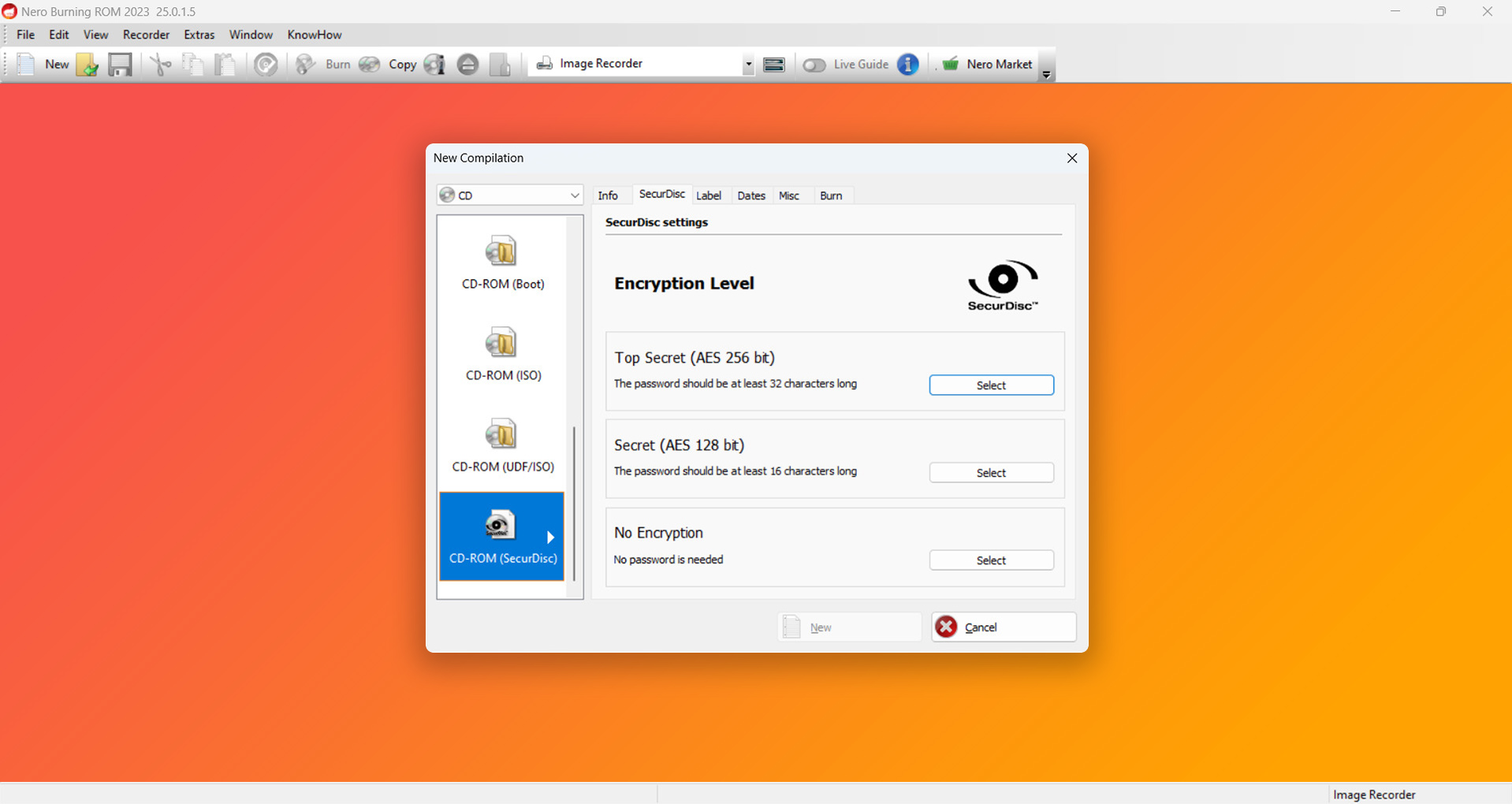

The Cocoa Press chocolate 3D printer brings the ability to print chocolate to the consumer market by way of a DIY kit 3D printer. Loosely based on a Voron design, the Cocoa Press has a build volume of 140 x 150 x 150 mm and can extrude up to 65 grams of chocolate in a single print. Equipped with a large and colorful LCD touchscreen that plays musical fanfare upon completion of a print, the Cocoa Press is marketed not just at those with 3D printer experience but anyone interested in printing chocolate at home.

3D Chocolate Printer DIY Kit

(Image credit: Cocoa Press)

For now, available only at Cocoa Press Site for $1,499

The Cocoa Press is a surprisingly difficult machine to rate. Priced at $1,499 for a kit (without the required printed parts) and requiring about 10 hours for assembly, the Cocoa Press is unlikely to be an impulse buy for most consumers. Bakeries, pastry shops, and chocolatiers looking to create custom geometry not possible with a mold are target customers, but the learning curve for this technology may be a bit steeper for those without previous additive experience.

The 65 gram chocolate cores areavailable for $49 / 10 pack , which prices each refill of the machine at $4.90. All things considered, I believe the Cocoa Press is a step in the right direction for printing chocolate at home and it’s earned a spot on our list of thebest 3D printers .

Specifications of Cocoa Press

Swipe to scroll horizontally

| Machine Footprint | 14.37 x 12.40 x 27.56 inches (365mm x 315mm x 700mm) |

|---|---|

| Build Volume | 5.51 x 5.91 x 5.91 inches (140mm x 150mm x 150mm) |

| Material | Dark, Milk, and White Chocolate |

| Cartridge Size | 65 grams |

| Nozzle | .8mm, 1.6mm |

| Bed Leveling | 25-Point Automatic Mesh Leveling |

| Printing Speed | 25-40mm/s |

| Build Platform | Flexible Removable Silicone Mat |

| Connectivity | USB, SD Card |

| Firmware | Custom Marlin |

What is the Cocoa Press?

The Cocoa Press is a chocolate 3D printer which converts 3D models into printed parts made out of chocolate. Printing food is difficult, and printing chocolate is especially hard due to the precision required to heat the material up enough to extrude, but not so much that it remains molten after extrusion. The mechanical process is similar toFFF 3D printers , but with specific considerations for the chocolate material.

LATEST VIDEOS FROM tomshardware Tom’s Hardware

(Image credit: Cocoa Press)

CEO and founderEllie Weinstein ( Full disclosure: I’ve known Ellie since before the launch of this printer ) has been working on printable chocolate since 2014, which resulted inmultiple iterations of the chocolate printer and various strategies for bringing the technology to market. Cocoa Press is not a one-person operation, and the growth in contributors has led to the most recent iteration of the Cocoa Press machine. The current Cocoa Press is a modified Voron design that uses a special toolhead to bring chocolate up to temperature and uses a plunger to push it through the cartridge and out of the nozzle.

I have experience with food printers (I built afrosting 3D printer based on aclay extruder design by Constantijn ) and also with printing chocolate specifically (amiserable experience with the barely-functional Wiiboox Luckybot ), so I’ve been excited to try a newer and more simplified process for printing chocolate.

Chocolate Material used by the Cocoa Press

(Image credit: Tom’s Hardware)

Cocoa Pressoffers material in the form of 65 gram chocolate cores in dark, milk, and white variants. This material is priced at $49 for a 10 pack, which breaks down to under $5 per core. To go further: this is equal to $0.08 per gram, which is roughly three times theprice per gram of a Snicker bar . If you’ve never tried to process chocolate before, this may seem like a high price for a solid bar of chocolate. It’s worth noting that the Cocoa Press is not a locked or proprietary system, but the difficulty in creating a solid block of chocolate will likely come as a surprise to consumers who have never attempted it before.

(Image credit: Cocoa Press)

On theFAQ page , Cocoa Press indicates that users are able to use their own chocolate with this printer, with the caveat that it will “require a fair amount of experimentation to get working ”. In my experience, preparing chocolate for printing is a challenging process, as air bubbles form during pouring and are exceptionally difficult to remove. These air bubbles result in defects similar to what you would see in typical 3D printer filament that has absorbed moisture. If you’re concerned with the long-term use of the Cocoa Press and want to make sure you always have a source of material if the company disappears, you can always make your own.

Unpacking the Cocoa Press

Image 1 of 3

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

The Cocoa Press ships in two boxes: one with all the parts (except the 3D printed parts) required to build the machine, and one with the chocolate cores for 3D printing (10 dark, 5 milk, and 5 white chocolate). The parts box is densely packed with individual boxes, each labeled with the family of parts contained within. The Cocoa Press also includes a badge with a serial number for warranty paperwork (I watched the site like a hawk on release, and managed to get the first order in, which arrived with the first publicly available serial: SN: 0002).

(Image credit: Tom’s Hardware)

Each box is further labeled, with individual components bagged, tagged, and referenced in the documentation. The assembly process felt like building a LEGO kit or a Gundam model, where each step has all parts labeled and sorted separately so you’re not digging through a giant box full of nuts and bolts when looking for a single washer.

Printed Parts on the Cocoa Press

Image 1 of 2

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

A DIY kit 3D printer, the Cocoa Press uses 3D printed parts for several of the brackets, mounts, and other structural components. The parts are offered as adownload on Thangs for users who want to print them out themselves and save some money or add a level of customization. The recommended settings are included, as well as information regarding print orientation, color, etc. Several of the parts are also designed to accept a heat set insert, which are included (along with a soldering iron tip designed to fit them) with the kit.

Image 1 of 2

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

Cocoa Press also offers the printed parts as a bundle ($199 without the heat set inserts , and$249 with them already installed ). I ordered the printed parts with the heat set inserts already installed, as the cost was easily justified by the amount of time I would save not needing to print them myself. The parts were printed in PETG, and I was impressed with how clean everything looked.

(Image credit: Tom’s Hardware)

I had an issue with one heat set insert on the LCD enclosure that had been pressed in too far for the M3x8 bolt to reach it (pictured above). Fortunately, I had a spare M3x10 which was able to reach the insert and could pull the enclosure shut. This was the only issue with the printed parts I had, and I considered it a resolvable one that didn’t require a support ticket or replacement part.

Assembly and Design of the Cocoa Press

Image 1 of 3

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

Make no mistake: this is a kit 3D printer and will require time to assemble. Cocoa Press estimates the assemblyshould take about 10 hours , but it took me about 14 hours split across two days. I spent extra time making sure the aluminum extrusions were square, carefully wrapping the wires, and generally taking my time so I wouldn’t need to go back and fix anything later. I generally enjoy the process of building 3D printers (like the Creality Ender 3 V2,which I did a 1 hour speedrun on when it was released), and the Cocoa Press was no exception.

(Image credit: Tom’s Hardware)

The Cocoa Press has clearly been designed by someone who uses 3D printers, and the attention to detail shows in parts like the motor mounts, hot end Z-offset, and use of thumbscrew as quick-release fasteners. The CoreXY-inspired kinematic system uses an A and B belt to move the carriage across the X/Y plane, and the Z stage drops as the print height increases as opposed to lifting the extruder. Generally speaking, the assembly is similar to building aDIY kit 3D printer like a Voron up until the point where you start to assemble the hot end, which is where the changes become apparent.

Image 1 of 3

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

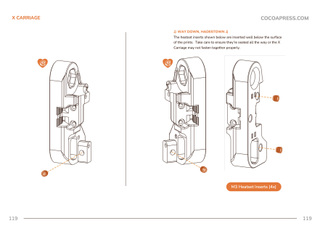

The hot end on the Cocoa Press feels almost comically oversized compared to most FFF 3D printers due to the unique considerations of printing chocolate. The Cocoa Press uses a pair of heating elements to heat the material: one for the body of the cartridge and one for the nozzle. The temperature requires precision to a tenth of a degree, and the heating elements (embedded on a sticker membrane) need to be carefully applied to outer surfaces of the cartridge to prevent air pockets from forming.

Image 1 of 3

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

Loading the material is a multi-step process. The extruder assembly uses a latch to keep it locked in place and when unlocked the assembly can be tilted backwards, allowing access to the cartridge. Removing the thumbscrew allows the cartridge to slide out and a 65 gram chocolate core can be inserted before pivoting the assembly and latching it in place. The chocolate is heated inside the cartridge and is pushed out of the nozzle via the small red plunger on the end of the threaded E rod.

(Image credit: Tom’s Hardware)

The entire process only takes a few minutes, but I found myself washing, cleaning, and drying the cartridge each time I swapped cores. This takes a good bit of time, and the newly inserted cartridge will take 20 minutes to warm up to printing temperature before printing.

If you’re going to be printing a lot, having multiple cartridges for hot-swapping would definitely be a smart move. The nozzles (both 0.8mm and 1.6mm) have an integrated registration feature that keeps them aligned with the heater body, allowing the thumbscrew to tightly hold the entire assembly in place.

Image 1 of 2

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

Wiring the Cocoa Press is similar to wiring most DIY kit 3D printers, and there are a few screw terminal blocks to connect, both on the 150 watt power supply as well as on the mainboard. This can be a bit daunting for a beginner, and I appreciated that Cocoa Press includes a printed cover for the PSU terminal block to prevent any accidental shorting while preventing access. Like other parts of this project, the best path forward is to work slowly and check the assembly guide regularly.

(Image credit: Tom’s Hardware)

The Cocoa Press is a tall printer, measuring over 27-inches in Z despite the relatively conservative 5.51 x 5.91 x 5.91 build volume. This is due to the height of the plunger mechanism which pushes the chocolate core through the cartridge. For storage, this assembly can be rotated back using the same process that’s used for swapping out material.

Cocoa Press Documentation and Troubleshooting

(Image credit: Cocoa Press)

The Cocoa PressDocumentation Page includes information on 3D printing, 3D printing with chocolate specifically, troubleshooting, and even a page on theethics of chocolate . In a market where 3D printing companies will frequently provide the absolute minimum amount of information, Cocoa Press deserves praise for going above and beyond to provide useful and actionable documentation to customers.

(Image credit: Cocoa Press)

The includedassembly guide for the Cocoa Press is a jaw-dropping 214 pages long; possibly the longest I’ve seen for a consumer 3D printer. Filled with whimsical references to musical theater (“Way Down, Hadestown ”), pop culture (“No Touching! ”), and generally good advice (“Trust but Verify ”), the manual succeeds in grabbing your attention and guiding you through the assembly process with humor, which can be a challenge for a typically dry piece of technical writing.

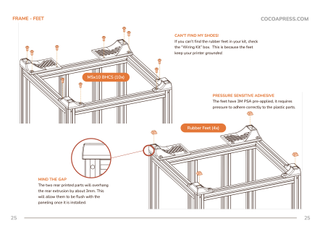

(Image credit: Cocoa Press)

The assembly guide has a way of staying one step ahead of you during the process, with helpful tips like “Can’t find my shoes! ” indicating the rubber feet for the printer may be in a place you aren’t expecting them. This was exactly what happened to me, and right at the moment I was wondering where the rubber feet were, the assembly guide was prepared and ready.

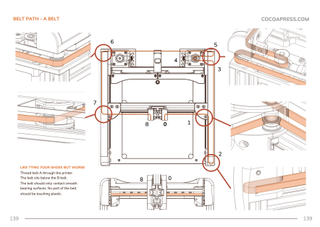

(Image credit: Cocoa Press)

Where the assembly guide really shines is in the most difficult parts of assembly, like routing the timing belts for the X and Y axes. This process (indicated in the manual as “Like tying your shoes but worse ”) is a difficult one and can sometimes feel like you need 4 hands to complete it.

The guide includes not only a picture of the full belt path, but also cutaway views showing belt routing over every pulley, idler, and connection point. This is normally the spot in an assembly where I would try to find a video on YouTube to check my work, but the included documentation was more than enough to give me confidence in my assembly skills.

Calibrating and Leveling the Cocoa Press

(Image credit: Tom’s Hardware)

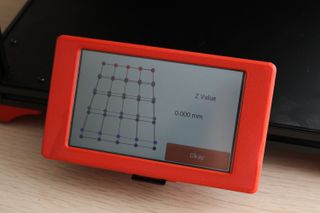

Similar to printers like thePrusa MK3S+ (one of thebest 3D printers ), the Cocoa Press uses an inductive probe to detect the location of the build platform at various points to create a mesh used for leveling. This probe is attached to the X carriage, and is located directly behind the extruder module.

(Image credit: Tom’s Hardware)

The printer UI has a guided “Probe Mesh” operation which will automatically move the print head to 25 points on the build platform, measure the offset, and store the data. Once complete, the resulting mesh can also be viewed in the printer UI to show the general distortion in the form of a 3D mesh.

This is helpful, and when I first ran the operation I noticed that my bed skewed heavily to the right. After removing the print bed and reassembling it, the distortion was reduced. This was a helpful visualization, and worked well to diagnose and resolve my issue.

Build Platform on Cocoa Press

(Image credit: Tom’s Hardware)

The Cocoa Press includes several silicone mats that act as a build surface. These mats are thin and flexible, and the chocolate sticks to them while printing but easily peels off once the print is complete. The mat is held in place with four thumbscrews which keep it flat against the steel build platform.

(Image credit: Tom’s Hardware)

The mats are designed to be washed with soap and water, and I found them to be easy to clean after printing. Because I was careful not to purge my nozzle onto the mat when replacing chocolate, they didn’t get much chocolate on them during use. After printing, I would typically remove the printed part and use the included scraper to remove the purge line, which peels up in a single piece. Similarly, the initial extrusion when loading material can also be popped off and eaten as a quick snack, not typically the case with an FFF-style 3D printer.

Printing Demo Models on the Cocoa Press

Image 1 of 2

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

The Cocoa Press includes several demo models preloaded on the included SD card as well as apage on Printables that has three models available for download. The Fidget Skull by Clockspring is an impressive display of the Vase Mode functionality of the Cocoa Press, which uses a single continuous helical toolpath to create a 3D print. However, this model uses nearly an entire core of material (worth $4.90), which may be more than some users want from a demo model.

Image 1 of 2

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

Switching to the 1.6mm nozzle, the infill samples are a fun way to show a few different infill patterns while only using a relatively small amount of material. Printed using dark chocolate, these samples all have a differentmouthfeel , a unique and fun effect caused by the crumbling of the infill as it is being chewed.

I appreciate that the Cocoa Press includes both simple and ambitious demo models, as this is a frequently overlooked aspect of consumer 3D printers that can lead to frustration for first-time users. I think about theCreality LD-002R , a resin 3D printer that included a demo print that took over 19 hours to complete with no indication of print time in the model name. Obviously, that’s not ideal for someone looking to quickly verify the machine is operational.

## Slicing Software for Cocoa Press

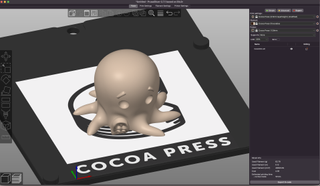

Model:Cute Octopus Says Hello by Makerbot (Image credit: Prusa)

The Cocoa Press uses PrusaSlicer to prepare models for printing, a welcome change from manufacturers that will fork and abandon Open Source software to get their name at the top of the application. The latest version of PrusaSlicer includes machine profiles for the Cocoa Press, both with the 0.8mm nozzle and the 1.6mm nozzle.

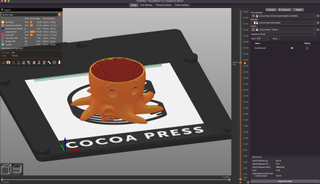

Model:Cute Octopus Says Hello by Makerbot (Image credit: Prusa)

PrusaSlicer allows users to import a 3D model and make adjustments to various parameters like infill type and amount, print speed, etc. In addition to the machine profiles included with the Cocoa Press, the print and material profiles worked perfectly during testing. I found myself only modifying the infill type and amount to change the amount of material used during printing.

Image 1 of 2

(Image credit: Prusa)

Model:Heart by Lumorion

(Image credit: Prusa)

Model:Heart by Lumorion

PrusaSlicer offers basic CAD manipulation, so users can add text, adjust print parameters, and even include modifiers without needing additional software. Using theHeart model by Printables user Lumorion , I made several changes to the model, including reducing Z height, adding text, and removing top layers from a portion of the print. After checking the toolpath preview, I saved the .gcode file to the SD card and brought it to the printer.

Image 1 of 2

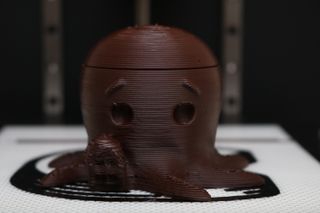

Nero Burning ROM:

Nero Burning ROM:

The ultimate burning program for all your needs!

(Image credit: Prusa)

Model:Heart by Lumorion

(Image credit: Prusa)

Model:Heart by Lumorion

The resulting print looked exactly how I wanted it to. The top surface is smooth, and the open portion on the top of the heart clearly shows the gyroid infill that fills the model. The text is clear and legible, and the sidewalls are smooth and even. The ability to rapidly customize 3D models without needing to use CAD software is a huge bonus for anyone using this model to create chocolate parts without a mold.

Image 1 of 2

(Image credit: Tom’s Hardware)

Model:Cute Octopus Says Hello by Makerbot

(Image credit: Tom’s Hardware)

Model:Cute Octopus Says Hello by Makerbot

Using the 0.8mm nozzle, I printed the Cute Octopus Says Hello model by Makerbot using dark chocolate, a dense gyroid infill, and an otherwise standard 0.5mm layer height profile. The sidewalls printed smooth and consistent, and if you didn’t know it was chocolate, you may even think it’s just dark brown ABS filament based on the layers. The gyroid infill is hypnotic to watch during printing, and tastes just as good as it looks.

Model:Cute Octopus Says Hello by Makerbot (Image credit: Tom’s Hardware)

After printing, I noticed there was a line in the model right over the eyebrows. This line was caused by a skipped layer, an issue that appeared and then resolved itself before the next layer. In addition, the tentacle at the front of the model looks a bit warped, likely due to the small cross-sectional area not having enough time to cool between layers. I didn’t encounter the first issue again while printing, but I did notice that tall, thin parts had trouble resolving, an issue shared by other FFF printers but made worse due to the specific material used.

Image 1 of 2

(Image credit: Tom’s Hardware)

Model:Cute Octopus Says Hello by Makerbot

(Image credit: Tom’s Hardware)

Model:Cute Octopus Says Hello by Makerbot

Of course, it’s impossible to review a chocolate 3D printer without talking about the taste of the printed parts. The dark chocolate has a deep and rich flavor, and the experience of eating a sparsely-filled model is a truly interesting one. I described it initially as a similar feeling to eating cotton candy; where a volumetrically large amount of food rapidly shrinks in your mouth after biting into it. The infill crushes with only a little force, and the tiny broken pieces merge together as you chew. It’s a unique experience, and one that is difficult to explain.

Image 1 of 2

(Image credit: Tom’s Hardware)

Model:Easy Filament Swap Gingerbread Cookie by Overture3D

(Image credit: Tom’s Hardware)

Model:Easy Filament Swap Gingerbread Cookie by Overture3D

Inspired by the articulated fish model used in the Cocoa Press marketing, I prepared an articulated gingerbread man model using the default 0.5mm slicer profile and loaded milk chocolate. The model printed in about 30 minutes, and the detail on all features is clear and present.

Image 1 of 2

(Image credit: Tom’s Hardware)

Model:Easy Filament Swap Gingerbread Cookie by Overture3D

(Image credit: Tom’s Hardware)

Model:Easy Filament Swap Gingerbread Cookie by Overture3D

The articulation worked, and the model was capable of bending and holding in place. The chocolate slightly over-extruded around the joints, so the clearance was more of an interference fit that would hold in place after adjusting. The model held up to a reasonable amount of bending, and it’s easy to see how this technique could be used for other prints.

Image 1 of 2

(Image credit: Prusa)

(Image credit: Tom’s Hardware)

Ask yourself this: if you had a 3D scanner, a chocolate 3D printer, and a desire to print something unique, what would you make? Having previously made a 3D scan of my head (you can make one, too! ), I figured printing it in chocolate would be a fun thing to try out! I angled the model upwards in PrusaSlicer, and spent a good amount of time reducing the overhangs as much as possible. Knowing that steep overhangs may result in drooping perimeters, I did my best to angle the model in a way that reduced them as much as possible.

(Image credit: Tom’s Hardware)

The resulting print is equal parts hilarious and impressive. The culmination of multiple cutting-edge technologies, the ability to create a 3D scan and then print it in chocolate using equipment affordable to consumers is a fascinating development and is worth a moment of reflection. The print itself had a few minor issues (some cooling around the top of the head, and a retraction seam appeared near the lips), but the result would make a great wedding cake topper.

Image 1 of 2

(Image credit: Prusa)

Model:Chocolate Bunny by ncsandor

(Image credit: Prusa)

Model:Chocolate Bunny by ncsandor

I found the milk chocolate to be particularly sensitive to overhangs while printing, as seen on the mouth of theChocolate Bunny by ncsandor . While the model looks generally good, the overhang contours on the mouth sagged during printing as they had nothing underneath to support them. Because printing with supports wouldn’t likely make sense for this model, the alternatives are either directly manipulating the 3D model or angling the print to reduce the overhang.

Image 1 of 2

(Image credit: Tom’s Hardware)

(Image credit: Tom’s Hardware)

Going for a more ambitiously featured model, I printed the Benchy (a standard geometry typically used as aspeed benchmark for the fastest 3D printers ) using white chocolate. I let the chocolate warm up for the recommended 20 minutes, but the first print (pictured above on the left) looked a bit uneven in the thin spots, and there were multiple lines in the hull.

Running the print a second time (pictured above on the right) immediately after the first print completed resulted in a much cleaner and better resolved 3D model. Similar to making a second batch of pancakes immediately after the first, the quality increases visibly between prints.

Bottom Line

(Image credit: Tom’s Hardware)

At $1,499 forthe bare-bones kit and another$250 for the printed parts with inserts , the Cocoa Press is not a cheap printer relative to desktop machines like theElegoo Neptune 4 Pro . However, the ability to print chocolate straight out of the box is not something that can be done easily, and the Cocoa Press is one of the least expensive options for printing food at home.

The Cocoa Press is not a printer for everybody, but the overall experience of building, using, and enjoying the printer is something that I suspect will resonate very deeply with a specific group of customers. A true DIY kit, the Cocoa Press is a weekend project to assemble and requires a reasonable level of mechanical skill and troubleshooting ability to put together correctly.

If you’re interested in creating custom chocolates without needing to make a mold, the Cocoa Press is a great place to start. If you’re an additive manufacturing enthusiast looking to expand the scope of your experience (like me), the Cocoa Press is an excellent tool to take conventional DFAM principles and apply them to a new and challenging material. I have no problem recommending the Cocoa Press, and even included it on our roster of thebest 3D printers under the newly created ‘Best Food 3D Printer’ category. For more traditional and affordable options, check out ourbest budget 3D printers list.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers

- Title: Exploring Hardware with Tom: A Comprehensive Guide

- Author: George

- Created at : 2024-08-19 03:04:13

- Updated at : 2024-08-20 03:04:13

- Link: https://hardware-tips.techidaily.com/exploring-hardware-with-tom-a-comprehensive-guide/

- License: This work is licensed under CC BY-NC-SA 4.0.

.png) Kanto Player Professional

Kanto Player Professional

vMix Pro - Software based live production. vMix Pro includes everything in vMix 4K plus 8 channels of Replay and 8 vMix Call

vMix Pro - Software based live production. vMix Pro includes everything in vMix 4K plus 8 channels of Replay and 8 vMix Call WinUtilities Pro

WinUtilities Pro

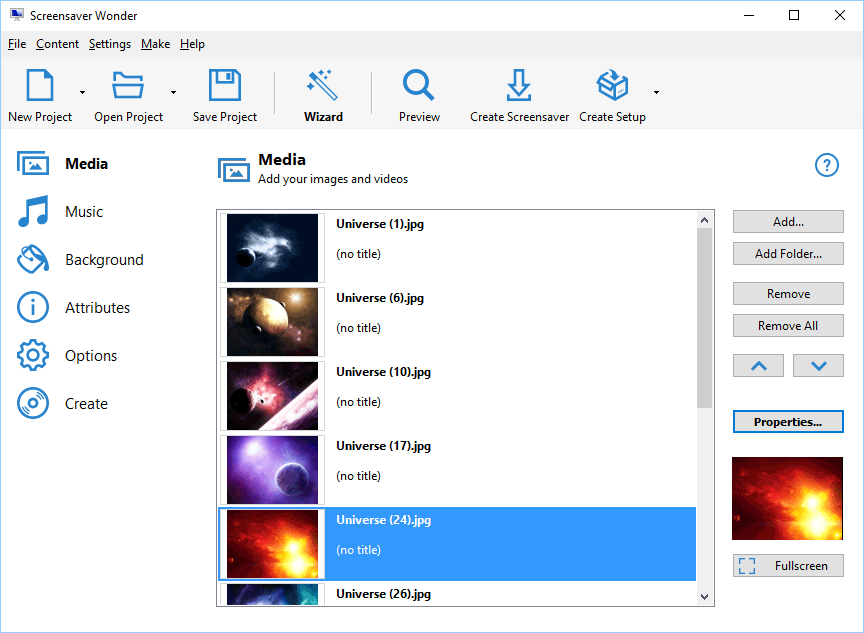

With Screensaver Wonder you can easily make a screensaver from your own pictures and video files. Create screensavers for your own computer or create standalone, self-installing screensavers for easy sharing with your friends. Together with its sister product Screensaver Factory, Screensaver Wonder is one of the most popular screensaver software products in the world, helping thousands of users decorate their computer screens quickly and easily.

With Screensaver Wonder you can easily make a screensaver from your own pictures and video files. Create screensavers for your own computer or create standalone, self-installing screensavers for easy sharing with your friends. Together with its sister product Screensaver Factory, Screensaver Wonder is one of the most popular screensaver software products in the world, helping thousands of users decorate their computer screens quickly and easily. The Tube Sites Submitter is a fast and efficient tool for anyone who needs to upload videos quickly, easily and automatically to hundreds of tube sites in mere minutes .

The Tube Sites Submitter is a fast and efficient tool for anyone who needs to upload videos quickly, easily and automatically to hundreds of tube sites in mere minutes .

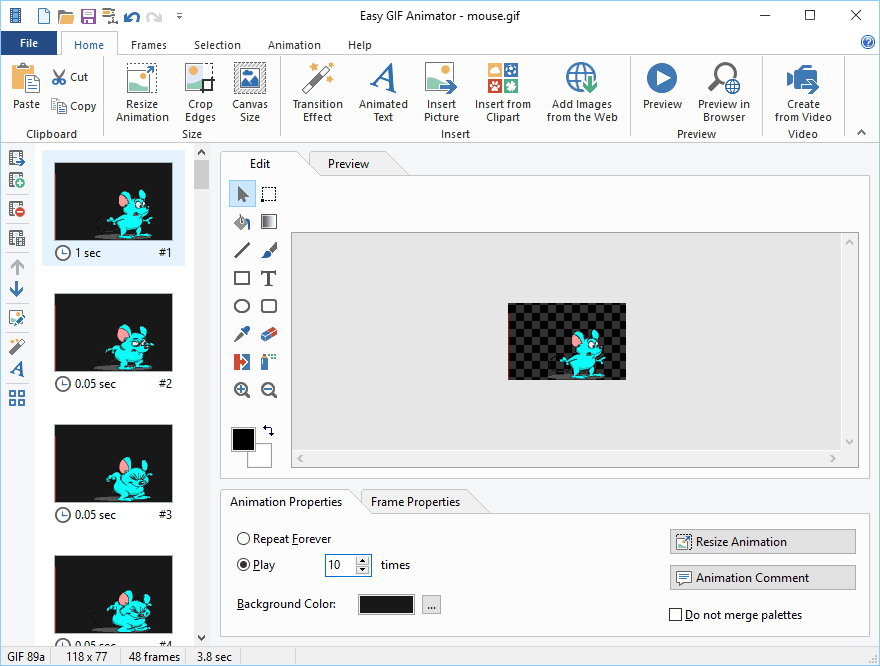

Easy GIF Animator is a powerful animated GIF editor and the top tool for creating animated pictures, banners, buttons and GIF videos. You get extensive animation editing features, animation effects, unmatched image quality and optimization for the web. No other GIF animation software matches our features and ease of use, that’s why Easy GIF Animator is so popular.

Easy GIF Animator is a powerful animated GIF editor and the top tool for creating animated pictures, banners, buttons and GIF videos. You get extensive animation editing features, animation effects, unmatched image quality and optimization for the web. No other GIF animation software matches our features and ease of use, that’s why Easy GIF Animator is so popular.

EaseText Audio to Text Converter for Windows (Personal Edition) - An intelligent tool to transcribe & convert audio to text freely

EaseText Audio to Text Converter for Windows (Personal Edition) - An intelligent tool to transcribe & convert audio to text freely

Jutoh is an ebook creator for Epub, Kindle and more. It’s fast, runs on Windows, Mac, and Linux, comes with a cover design editor, and allows book variations to be created with alternate text, style sheets and cover designs.

Jutoh is an ebook creator for Epub, Kindle and more. It’s fast, runs on Windows, Mac, and Linux, comes with a cover design editor, and allows book variations to be created with alternate text, style sheets and cover designs.

LYRX is an easy-to-use karaoke software with the professional features karaoke hosts need to perform with precision. LYRX is karaoke show hosting software that supports all standard karaoke file types as well as HD video formats, and it’s truly fun to use.

LYRX is an easy-to-use karaoke software with the professional features karaoke hosts need to perform with precision. LYRX is karaoke show hosting software that supports all standard karaoke file types as well as HD video formats, and it’s truly fun to use.