Mastery Guide: Overcoming Layer Misalignment Challenges in 3D Print Technology

Revolutionary Printing Speed Attained: Modified 3D Printer Renders ‘Speed Benchy’ Model in Record Time

Printing anything on a 3D printer is an exercise in patience. Though speeds have increased a great deal over the past two years, even thebest 3D printers take hours to finish a medium-sized project. Even small prints such as Benchy, a boat model that enthusiasts use for testing, require 13 to 30 minutes on thefastest 3D printers we’ve tested.

Amazingly, Maker Monika McWuff was able to output a Benchy in justtwo minutes and 9 seconds , thanks to her custom-modified Ender 3 Pro printer and its 120mm/s³ flow rate. She had posted an earlier video of the printer completing the task in 2 minutes and 19 seconds.

Only the 2:19 time has so far made the#SpeedBoatRace LeaderBoard , a list of prints that follow the officialSpeed Benchy rules .Annex Engineering verifies the claims so perhaps the 2:09 time hasn’t been verified yet. Either way, McWuff holds the new world record, besting a maker named Beraval who posted atime of 2:40 in 2022.

We should note that Speed Benchy prints don’t necessarily look great and don’t have to in order to make the leaderboard. McWuff’s 2:09 print has a ton of stringing and mush.

LATEST VIDEOS FROM tomshardware Tom’s Hardware

(Image credit: Monika McWuff)

Surprisingly, McWuff is new to 3D printing, having purchased her first Ender 3 Pro less than a year ago to make parts for an RC car. She got the inspiration to modify an Ender after watching 247 Printing’s sub 3 minute Benchy and thought, “Pfff, how hard could it be?”

She bought a used Ender 3 Pro off eBay for $80 to start the project, then researched and taught herself how to make the necessary mods over the course of five months. McWuff admits she can get kind of obsessive about projects, and “if you can speed run it, I will make it fast!”

Some of her mods are fairly standard, like KevinAkaSam’s Belt Driven Ender 3 , which replaced the Z rods with, you guessed it, belts. This allows the printer to run smooth, straight and precisely in sync.

Stay On the Cutting Edge: Get the Tom’s Hardware Newsletter

Get Tom’s Hardware’s best news and in-depth reviews, straight to your inbox.

Contact me with news and offers from other Future brands Receive email from us on behalf of our trusted partners or sponsors

By submitting your information you agree to theTerms & Conditions andPrivacy Policy and are aged 16 or over.

Other mods are pure out-of-the-box thinking, like using a floor blower for cooling and bolting the printer to a 45-pound rubber bumper plate from the gym. “I used wood screws and some brackets to screw the printer down to the plate and dissipate energy,” she said.

(Image credit: Monika McWuff)

There isn’t a lot of the original Ender 3 Pro left, just a few aluminum extrusions and part of the bed, now covered in a sheet of carbon fiber. She uses her stock Ender 3 Pro in a tented enclosure to print ABS parts for the project.

The printer has 9 motors all together, with one for the extruder, four on the Y axis, two on the X axis, and two more on the Z axis. She said the motors are LDO, and she got an extra Ender 3 board from a friend to run it all. The machine also requires a second power supply, which is just laying randomly under the printer.

The hotend is especially interesting, and can push plastic faster than silly string . It’s a Trianglelab STD6 with a ceramic heating core, two extensions and a .4 CHT Volcano nozzle. A recent test clocked the flow rate at 120mm/s³. She’s hoping to get even more out of it by switching to a CHT V6 extender and a .5 Volcano nozzle.

(Image credit: Monika McWuff)

McWuff is using OrcaSlicer, and though Speed Boat Rules have restrictions on layer height and line widths, there’s plenty of wiggle room in other settings. She said the gcode is modified by hand so she can alter the temperature from 235 degrees for the first layer, 265 for the hull, then 215 for the cabin and 200 to finish. The print speed tops out at 800 mm/s for infill and inner walls, with an acceleration rate of 50,000mm/s². That’s five times faster than a Bambu Lab A1 .

A complete tour of the printer is on Monika’s YouTube channel here .

We’ve clocked a few fast Benchies at Tom’s Hardware , but since we’re testing stock printers and standard slicers settings, none have pushed plastic faster than the K1 Max with it’s 13 minute, 50 second Benchy.

For reference, a stock Ender 3 Pro running at it’s normal 50mm/s and using Speed Boat settings can print a Benchy in one hour and four minutes. With high-speed, Klipper firmware installed, the stock machine can comfortably run at 150mm/s and print a Benchy in 42 minutes.

- Title: Mastery Guide: Overcoming Layer Misalignment Challenges in 3D Print Technology

- Author: George

- Created at : 2024-08-19 03:21:40

- Updated at : 2024-08-20 03:21:40

- Link: https://hardware-tips.techidaily.com/mastery-guide-overcoming-layer-misalignment-challenges-in-3d-print-technology/

- License: This work is licensed under CC BY-NC-SA 4.0.

Greeting Card Builder

Greeting Card Builder

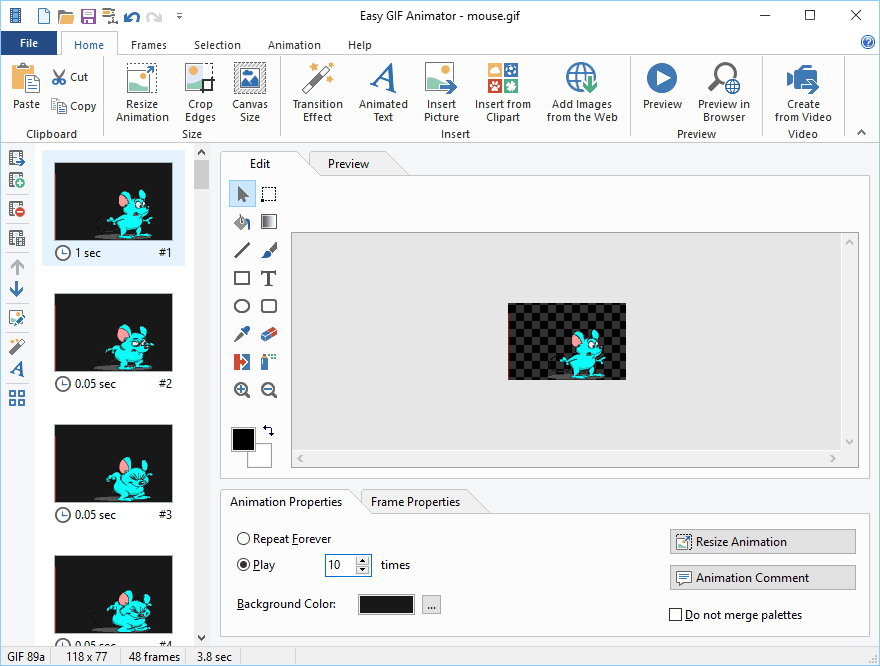

Easy GIF Animator is a powerful animated GIF editor and the top tool for creating animated pictures, banners, buttons and GIF videos. You get extensive animation editing features, animation effects, unmatched image quality and optimization for the web. No other GIF animation software matches our features and ease of use, that’s why Easy GIF Animator is so popular.

Easy GIF Animator is a powerful animated GIF editor and the top tool for creating animated pictures, banners, buttons and GIF videos. You get extensive animation editing features, animation effects, unmatched image quality and optimization for the web. No other GIF animation software matches our features and ease of use, that’s why Easy GIF Animator is so popular.